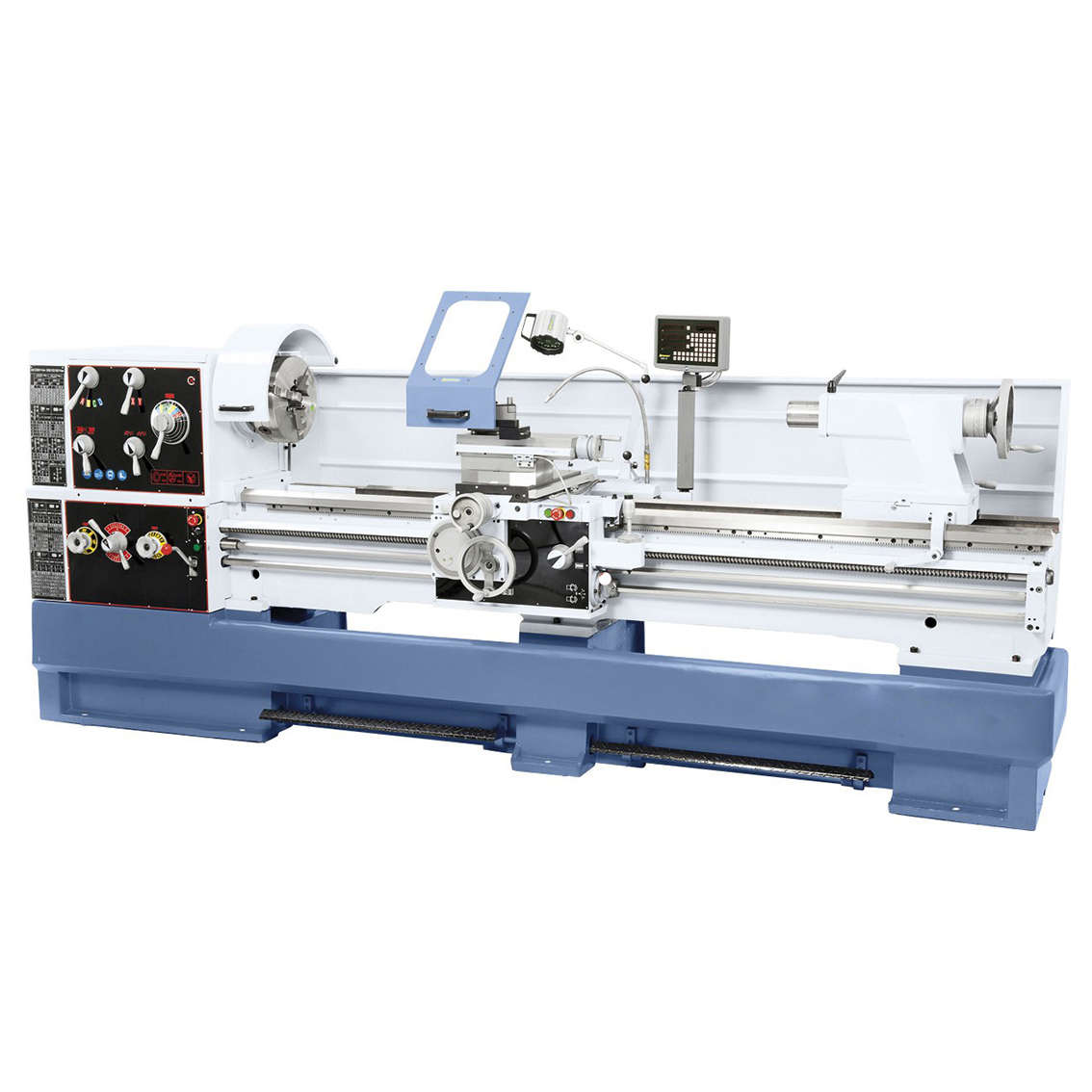

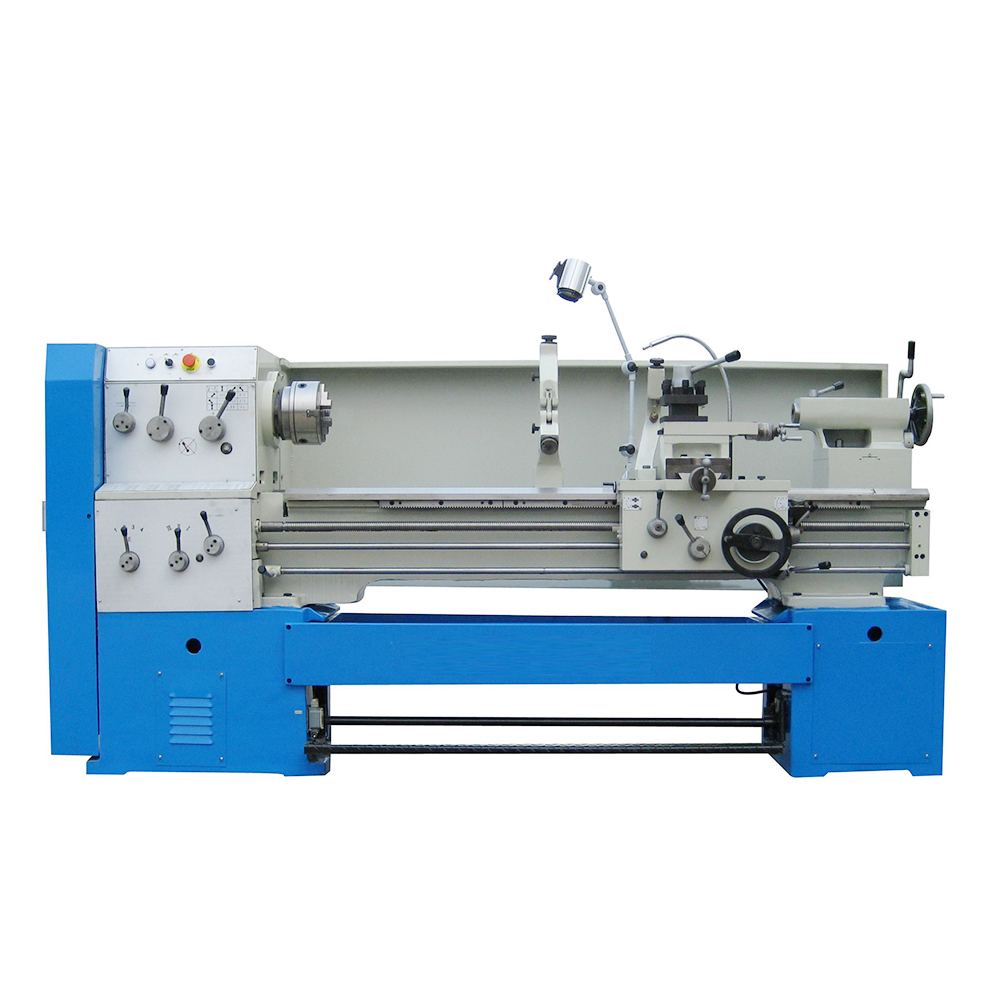

Mechanical Metal Lathe Machine C6241

Features

The guide way and all gears in the head stock are hardened and precision ground.

The spindle system is high rigidity and accuracy.

The machines have powerful head stock gear train, high rotating accuracy and smooth running with low noise.

An overload safety device is provided on the apron.

Pedal or electromagnetic braking device.

Tolerance test certificate, test flow chart included

The machines have powerful headstock gear train, high rotating accuracy and smooth running

with low noise.

An overload safety device is provided on the apron.

Pedal or electromagnetic braking device.

Tolerance test certificate, test flow chart included

The machines have powerful headstock gear train, high rotating accuracy and smooth running

with low noise.

An overload safety device is provided on the apron.

Pedal or electromagnetic braking device.

Tolerance test certificate, test flow chart included

| STANDARD ACCESSORIES: | OPTIONAL ACCESSORIES |

| 3 jaw chuck

Sleeve and center Oil gun |

4 jaw chuck and adapter

Steady rest Follow rest Driving plate Face plate Working light Foot brake system Coolant system |

Specifications

|

MODEL |

C6241 |

|

|

Capacity |

|

|

|

Swing over bed |

410 |

|

|

Swing over cross slide |

220 |

|

|

Swing in gap diameter |

640 |

|

|

Distance between centers |

1000/1500 |

|

|

Valid length of gap |

165mm |

|

|

Width of bed |

300mm |

|

|

Headstock |

|

|

|

Spindle nose |

D1-6 |

|

|

Spindle bore |

58mm |

|

|

Taper of spindle bore |

No.6 Morse |

|

|

Range of spindle speed |

12 changes, 25~2000r/min |

|

|

Feeds and threads |

|

|

|

Compound rest travel |

128mm |

|

|

Cross slide travel |

285mm |

|

|

Max.section of tool |

25×25mm |

|

|

Lead screw thread |

6mm or 4T.P.I. |

|

|

Longitudinal feeds range |

42 kinds, 0.031~1.7mm/rev(0.0011"~0.0633"/rev) |

|

|

Cross feeds range |

42 kinds, 0.014~0.784mm/rev(0.00033"~0.01837"/rev) |

|

|

Threads metric pitches |

41 kinds, 0.1~14mm |

|

|

Threads imperial pitches |

60 kinds, 2~112T.P.I. |

|

|

Threads diametral pitches |

50 kinds, 4~112DP |

|

|

Threads module pitches |

34 kinds, 0.1~7MP |

|

|

Tailstock |

|

|

|

Quill diameter |

60mm |

|

|

Quill travel |

130mm |

|

|

Quill taper |

No.4 Morse |

|

|

Motor |

|

|

|

Main motor power |

5.5kW(7.5HP) 3PH |

|

|

Coolant pump power |

0.1kW(1/8HP) 3PH |

|

|

Dimension and weight |

|

|

|

Overall dimension(L×W×H) |

220×108×134 |

275×108×134 |

|

Packing size(L×W×H) |

225×112×162 |

280×112×156 |

|

Net weight |

1580kg |

1745kg |

|

Gross weight |

1845kg |

2050kg |

Our leading products include CNC machine tools,machining center, lathes, milling machines, drilling machines, grinding machines, and more. Some of our products have national patent rights, and all of our products are designed perfectly with high quality, high performance, low price, and excellent quality assurance system. The product has been exported to more than 40 countries and regions across five continents. As a result, it has attracted domestic and foreign customers and quickly promoted product sales We are willing to progress and develop together with our customers.Our technical strength is strong, our equipment is advanced, our production technology is advanced, our quality control system is perfect and strict, and our product design and computerized technology. We look forward to establishing more and more business relationships with customers around the world.