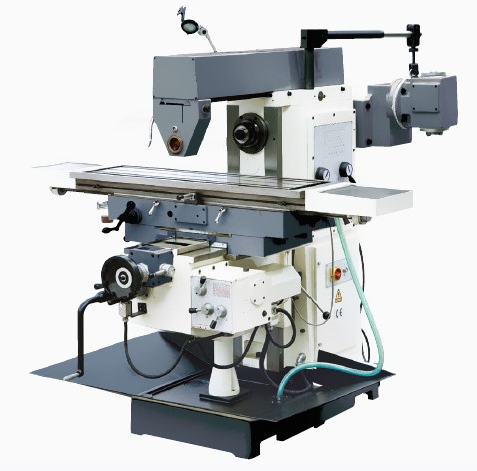

HMC1075 Horizontal CNC Metal Milling Machine

This machine tool is a double-station horizontal machining center, which adopts a T-shaped bed and is controlled by FANUC CNC system.It has functions such as automatic exchange of worktables, automatic indexing of turntables, and infinitely variable speed of spindles.It can make Straight line, diagonal and arc interpolation cutting, finish milling, boring,drilling,reaming,tapping etc to achieve four-side processing.It is suitable for the machining of box parts and complex parts in automobile, aerospace, metallurgical mining, machine tool manufacturing and so on.Machine tool has the characteristics of high efficiency, high precision, high rigidity and so on. It is an efficient equipment for enterprises to improve working efficiency and improve flexible machining of parts. It is also an ideal equipment for machining large and medium batches of parts.

| Item Model | Unit | HMC1075 |

| Size of worktable | mm | 1300*600 |

| Table travel around | mm | 1000 |

| Forward and backward travel of workbench | mm | 750 |

| Up and down stroke of spindle box | mm | 600 |

| Distance from spindle center to worktable surface | mm | 150-900 |

| Distance from spindle end to table center | mm | 90-690 |

| T-shaped groove for table | mm | 5-18*100 |

| Maximum load-bearing table | kg | 800 |

| Main motor power | kw | 7.5/11 |

| Spindle Taper | BT40 | |

| Spindle speed | rpm | 8000 |

| Cutting feed rate | mm/min | 1-10000 |

| Fast speed | m/min | 24/12/24 |

| X/Y/Z ball screw specification | - | 4012/5010/4012 |

| X/Z Axis rail specification | - | 45/55 |

|

Tool Magazine

|

- | Disc |

| Maximum tool diameter | mm | 112/200 |

| Maximum too length | mm | 400 |

| Maximum weight of tool | kg | 18 |

| Tool exchange time | sec | 3 |

| Minimum set unit of machine tool | mm | 0.001 |

| X/Y/Z orientation accuracy | mm | ±0.0075 |

| X/Y/Z repeated positioning accuracy | mm | ±0.005 |

| B axis positioning accuracy(table rotation) | “ | 10″ |

| B axis repeated positioning accuracy(table rotation) | “ | 5″ |

| Weight of machine tool | kg | 7500 |

| External dimensions | mm | 4600*3200*3000 |