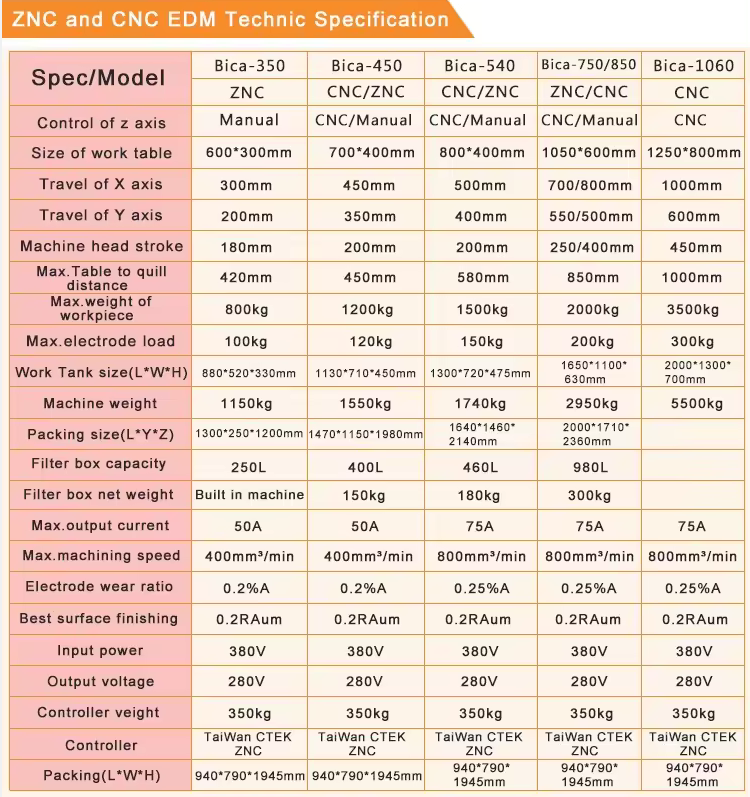

ZNC CNC 350 450 540 750 850 1060 High-speed EDM Sparking Erosion Forming Machine

Features

ZNC CNC 350 450 540 750 850 1060 High-speed EDM Sparking Erosion Forming Machine

1)Basic working fundamentals of the machine E

EDM is also known as electric spark machining. It’s a direct utilization of electrical energy and heat processing technology. It is based on during the spark discharge between the tool and the workpiece for removing excess metal in order to achieve the dimension, shape and surface quality of the predetermined processing requirements, as shown in Figure 1.EDM

Price,EDM

2) The composition of the machine

The EDM is made up of the main machine, working circulating fluid filtration system and power box. As shown in Figure 2.EDM P

(3)The main machine

The main machine is used for supporting the tool electrode and workpiece to ensure their relative position, and the realization of the reliable feeding of electrode in the process. It is mainly composed of bed, carriage, worktable, column, upper drag plate, spindle head, clamp system, clamp system, lubrication system and transmission machine. The bed and column is basic structures, which make positioned between the electrode, worktable and the workpiece. The carriage and the worktable is used to support the workpiece, through the transmission system to adjust the relative position of the workpiece. The adjustment condition could be directly informed by the data from the display, transformed by the grating ruler. The drag plate on the column can be lifted and moved to adjust the tool electrode to the optimal location. The fixture system is a clamping tool for electrode, which is fixed on the spindle head. The spindle head is a key component of the electric spark forming machine.Its structure is composed of servo feed mechanism, guide, anti twisting mechanism and auxiliary mechanism. It controls the discharge gap between the workpiece and the tool.

Lubrication system is used to ensure the humidification state of the mutual movement faces.EDM Price

,EDM Pr

4)Working liquid circulation filtration system.

Working liquid circulation filtration system includes working liquid tank, liquid pumps, filters,pipeline, oil tank and some others. They make the forced working fluid circulation.

5) In the power box.E

In the power box, the function of pulse power, which is exclusive for EDM processing, is to change industrial frequency exchanging current into one-way pulse current with certain frequency in order to supply the power to spark discharges for eroding metal. The pulse power has a great influence on technological and economic indicators, such as EDM processing productivity, surface quality, processing rate, processing stability and tool electrode loss.ED