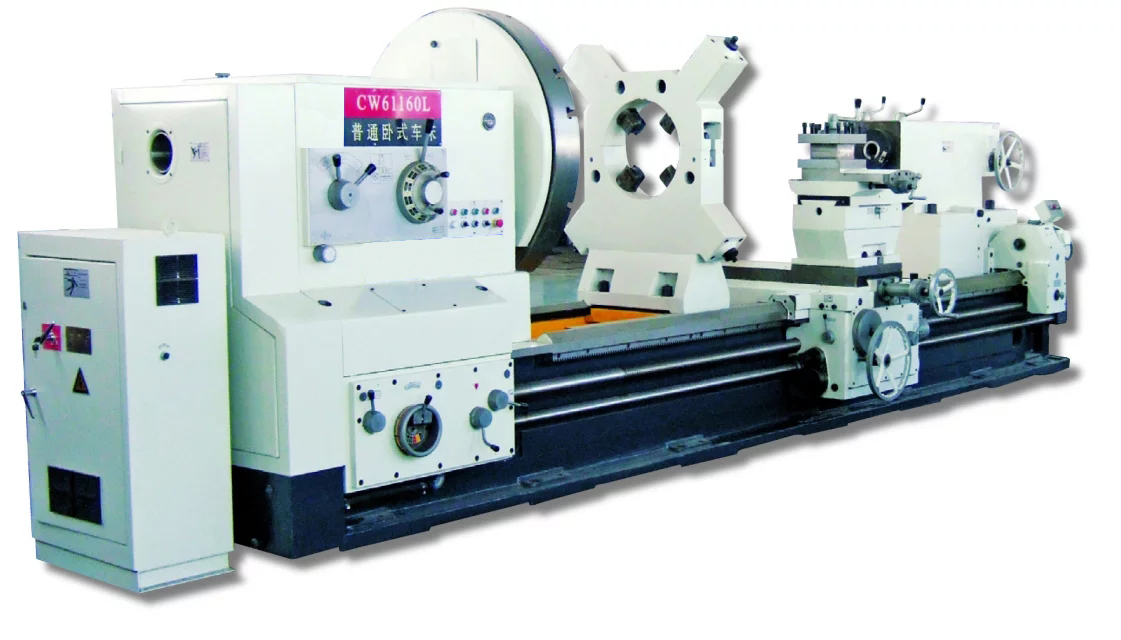

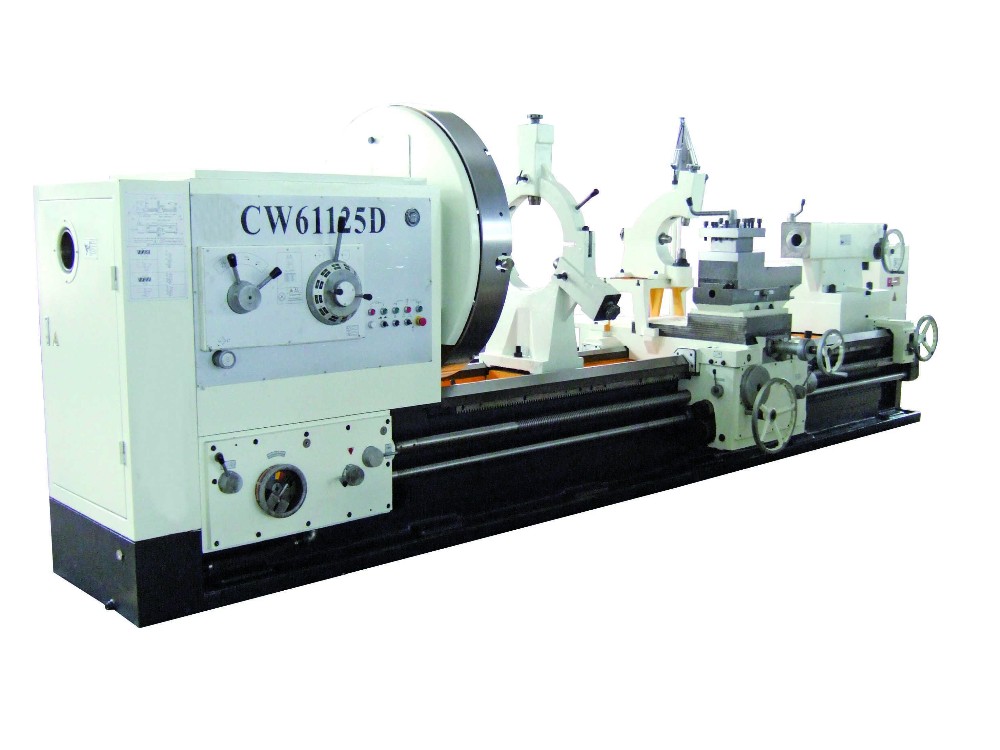

CW61200 Heavy Duty Turning Center Lathe Machine

Features

The lathe bed by integrally cast lathe bed structure, internal steel board layout is reasonable, has high rigidity, machine adopts the HT250, equipment with high frequency quenching, guide rail mill grinding process, stable machine tools with high precision, high rigidity, strong cutting.

Sliding box has a fast moving structure, single handle visualization operation;Spindle and reversing shift to the brake and the user can choose the hydraulic control or manual control machinery.

The machine tool rest with single motor turning cylinder, you can also use the tool rest and longitudinal feed turning cone length.The machine it is suitable for large and medium-sized of steel and non-ferrous metal parts processing, can be cylindrical turning, inner hole, face cutting, drilling, boring and nesting.

The machine tool power, strong rigidity, spindle speed range is wide, suitable for strong or high speed cutting.Of spindle brake and shift to the hydraulic control, sensitive and reliable braking available button without a stop conversion speed, the forced lubrication with pressure oil in the cabinet of the head of a bed, spindle speed range has several kinds, for user to choose from.

Has security structure in the sliding box, which can prevent damage of lathe due to overload.

Specifications

| Technical items Model | CW61200 |

| Swing diameter over bed | 2000mm |

| Swing diameter over carriage/cross slide | 1600mm |

| Swing diameter over gap/saddle | No gap |

| Max. Length of workpiece | 3000mm;4000mm; 5000mm; 6000mm; 8000mm; 10000mm; 12000mm; 14000mm; 16000mm; 18000mm; 20000mm |

| Max. Weight of workpiece | 16 tons |

| Spindle hole diameter | 130mm |

| Guide rail width | 1100mm |

| Main motor power | 22 kw |