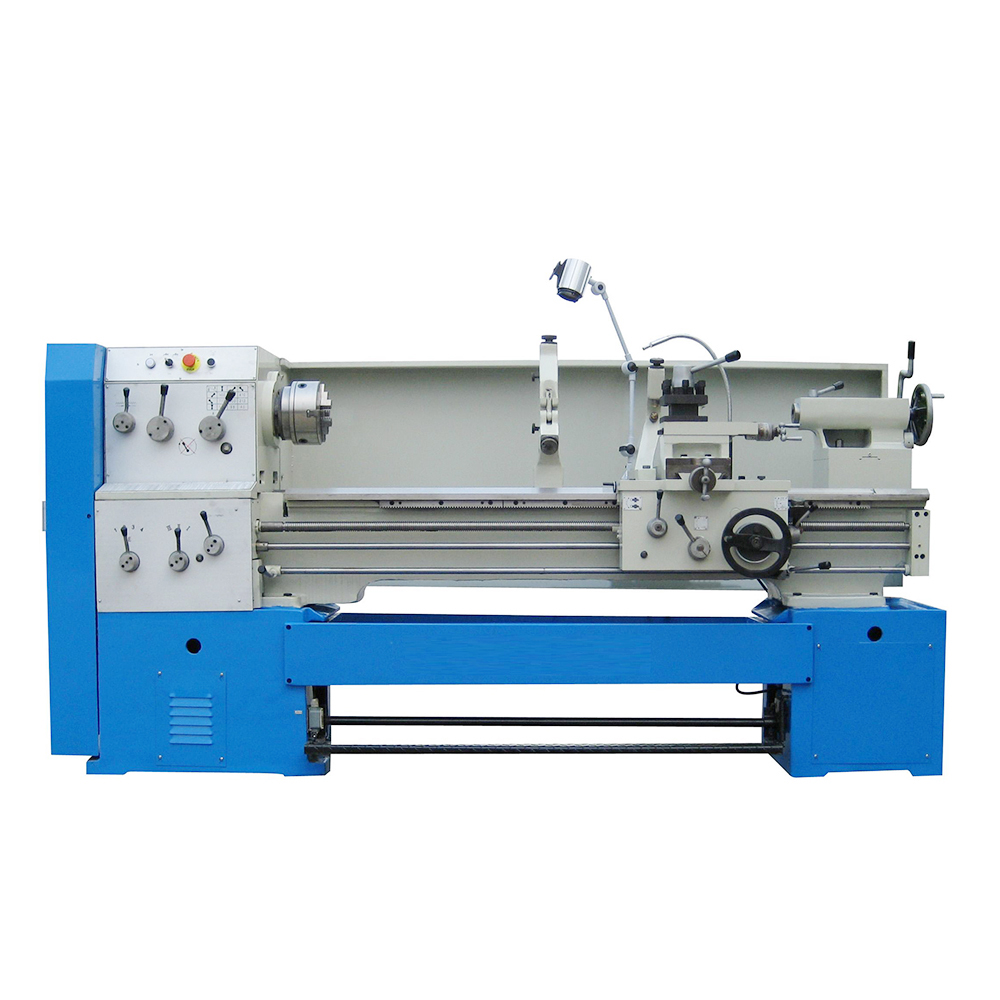

CS6240 Manual Lathe Machine

Features

This lathe has the advantages of high rotational speed, large spindle aperture, low noise, beautiful appearance, and complete functions. It has good stiffness, high rotational accuracy, large spindle aperture, and is suitable for strong cutting. This machine tool also has a wide range of applications, flexible and convenient operation, centralized control of the operating system, safety and reliability, fast movement of the slide box and middle slide plate, and the tail seat load device making movement very labor-saving. This machine tool is equipped with a taper gauge, which can easily turn cones. The collision stop mechanism can effectively control many features such as turning length.

It is suitable for all kinds of turning work, such as turning internal and external cylindrical surfaces, conical surfaces and other rotating surfaces and end faces. It can also process various commonly used threads, such as metric, inch, module, diameter pitch threads, as well as drilling, reaming and tapping. Broaching wire troughing and other work.

Specifications

|

Model |

UNIT |

CS6240B |

CS6240C |

|

|

Capacity |

Max. swing dia. over bed |

mm |

Φ400 |

|

|

Max. swing dia.in gap |

mm |

Φ630 |

||

|

Max. swing dia. over slides |

mm |

Φ200 |

||

|

Max. workpiece length |

mm |

1000/1500/2000/3000 |

||

|

Spindle |

Spindle bore diameter |

mm |

Φ82(B series) Φ105(C series) |

|

|

Taper of spindle bore |

|

Φ90 1:20 (B series) Φ113 1:20 (B series) |

||

|

Type of spindle nose |

no |

ISO 702/II NO.8 com-lock type(B&C series) |

||

|

Spindle speeds |

R/min |

24 steps16-1600 |

||

|

Spindle motor power |

KW |

7.5 |

||

|

Rapid traverse motoe power |

KW |

0.3 |

||

|

Coolant pump motor power |

KW |

0.12 |

||

|

Tailstock |

Diameter of quill |

mm |

Φ75 |

|

|

Max. travel of quill |

mm |

150 |

||

|

Taper of quill (Morse) |

MT |

5 |

||

|

Turret |

Tool O.D. size |

mm |

25X25 |

|

|

Feed |

Max.travel of upper toolpost |

mm |

145 |

|

|

Max. Travel of lower toolpost |

mm |

320 |

||

|

X axis feedrate |

m/min |

50HZ:1.9 60HZ:2.3 |

||

|

Z axis feedrate |

m/min |

50HZ:4.5 60HZ:5.4 |

||

|

X feed feeds |

mm/r |

93 kinds 0.012-2.73(B series) 65 kinds 0.027-1.07(C series) |

||

|

Z feed feeds |

mm/r |

93 kinds 0.028-6.43(B series) 65 kinds 0.063-2.52(C series) |

||

|

Metric threads |

mm |

48 kinds 0.5-224(B series) 22 kinds 1-14(C series) |

||

|

Inch threads |

t.p.i |

46 kinds 72-1/8(B series) 25 kinds 28-2(C series) |

||

|

Module threads |

πmm |

42 kinds 0.5-112(B series) 18 kinds 0.5-7(C series) |

||

|

Dia metric pitch threads |

DP |

45 kinds 56-1/4(B series) 24 kinds 56-4(C series) |

||

|

Packing size(mm) |

length |

2632/3132/3632/4632 |

||

|

width |

975 |

|||

|

height |

1270 |

|||

|

weight |

Kg |

2050/2250/2450/2850 |

||