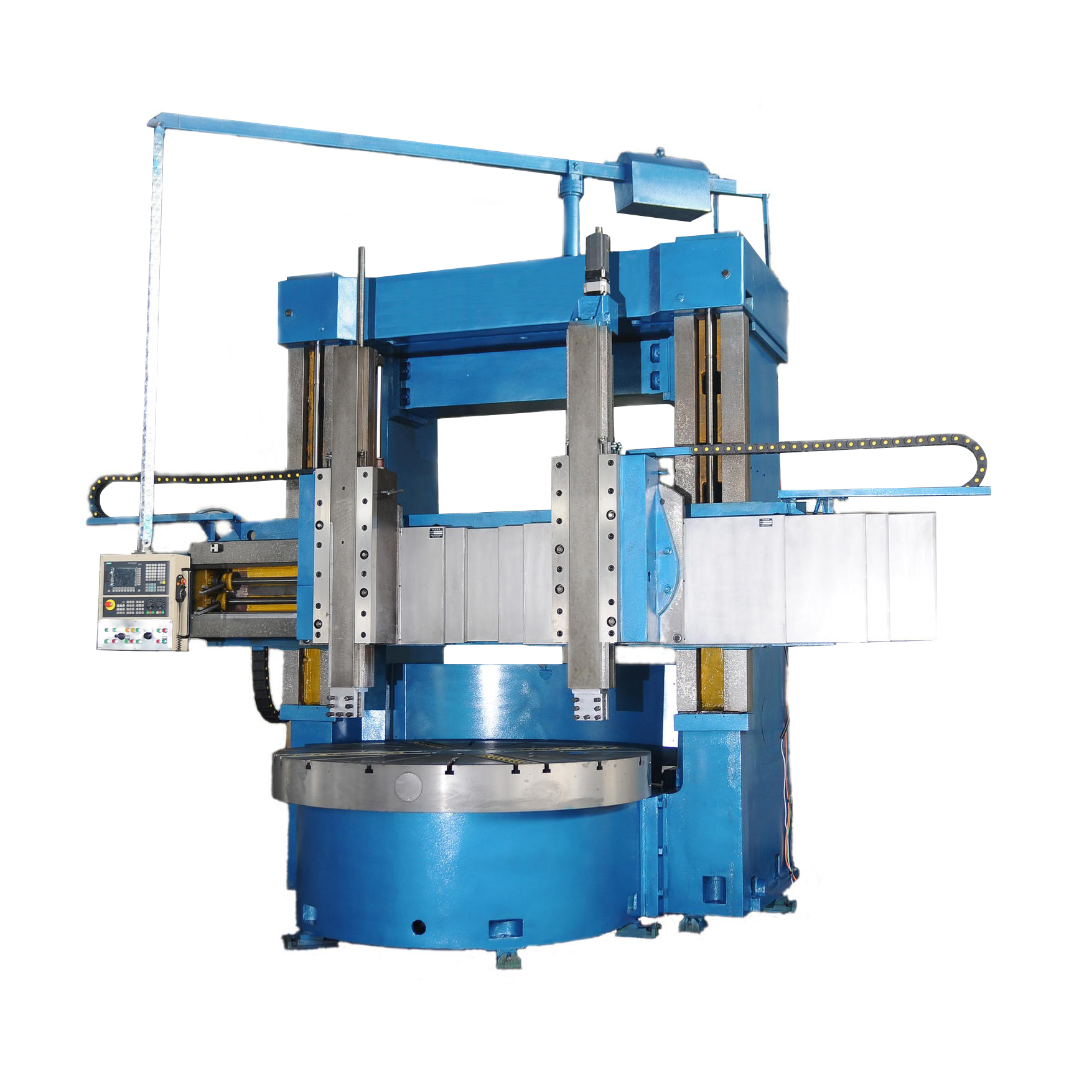

CK5240 CNC Lathe Vertical Milling Machine

Features

1.High quality resin sand casting technology is used in the large castings of the machine tool, after rough processing, the internal stress is eliminated scientifically by heat aging treatment, and the sliding surface of the machine tool is treated by sticking plastic, the wear resistance is improved by more than 5 times, and the precision retention of the guide rail is increased. The crossbeam and the slide seat of the crossbeam are equipped with an independent automatic centralized lubrication device.

2.All gearwheels use 40Cr gear-grinding gearwheels, with high rotation accuracy, low noise characteristics.

3.The machine tool consists of lathe bed, base, working table, crossbeam, crossbeam lifting mechanism, vertical tool post, CNC control system, ball screw rod, servo motor, hydraulic system, electrical system, button station and so on.

4.The main drive of the machine is driven by the main motor, the main shaft of the worktable is equipped with double-row cylindrical roller bearings. Its inner ring with taper can be adjusted, and the radial clearance can be adjusted to ensure the smooth operation of the spindle under high rotational speed precision. The main transmission mechanism and table guide rail are lubricated by pressure oil, and the working table guide rail is static pressure guide rail. The servo motor drives the ball screw rod to drive the sliding seat and the sliding pillow to move after the planetary reducer decelerates and increases the torque, realizes the X and Z axis feed.

5.Horizontal and vertical manual feed is operated by electronic hand wheel.

6.The crossbeam is firmly clamped on the vertical column, pressing the crossbeam lifting button on button station, through the electromagnetic slide valve to change the direction of the oil, so that the crossbeam is relaxed and make it move up and down by the motor.

Specifications

| MODEL | Unit | CK5240Q |

CK5240 |

| Max.turning diameter | mm | 4000 |

4000 |

| Max. height of work piece | mm | 1600/2000/2500 |

1600/2000/2500 |

| Max. weight of work piece | T | 10/20 |

32 |

| Worktable diameter | mm | 2830/3150 |

3200/3600 |

| Range of table speeds | r/min | 2-63 |

2-63 |

| Steps | 16 |

16 |

|

| Max torque of work table | KN.m | 63 |

100 |

| Rapid traverse of rail head | mm/min | 4000 |

4000 |

| Ram vertical travel of right railhead | Kn | 35 |

40 |

| Ram vertical travel of left railhead | kn | 30 |

30 |

| Range cutting force of right railhead | mm/min | 1-50 |

1-50 |

| Range cutting force of right railhead | mm/min | 0.1-1000 |

0.1-1000 |

| Travel of arm | mm | 1000 |

1250 |

| Section of arm | mm | 255×200 |

240×240 |

| Swivel of left and right railhead | ° | ±30° |

±30° |

| Section of tool | mm | 40×50 |

50×50 |

| Power of main motor | Kw | 55 |

75 |

| Overall dimensions | cm | 690×510×480/520 |

690×510×480/520 |